Take the guesswork – and frustration – out of diagnostics.

When sensor-driven technology meets connected crop management, you can expect the result to be an easier way to detect and manage pivot faults with Machine Diagnostics!

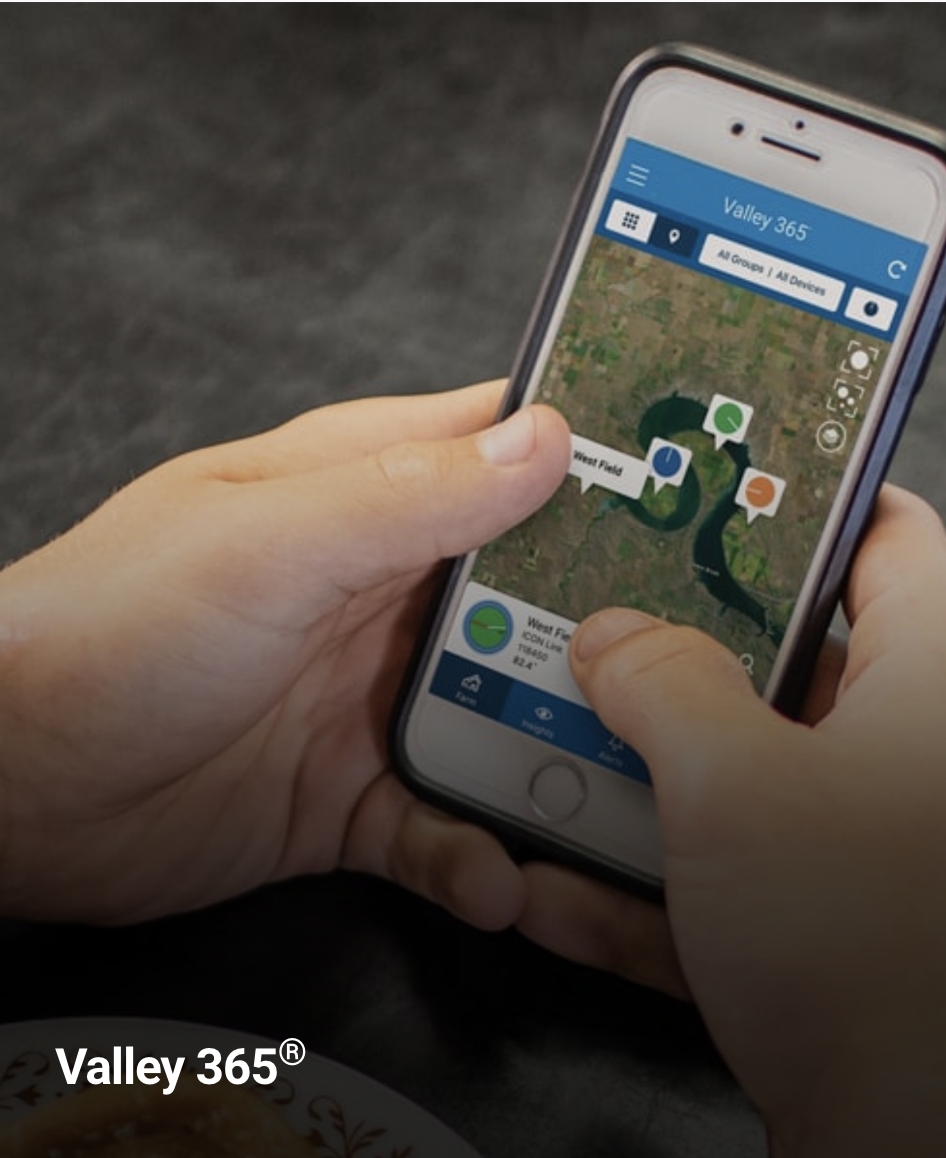

Now available within Valley 365, Machine Diagnostics* monitors key components of the machine and sends an alert directly to your device when an issue occurs so you can maximize uptime. No one wants to walk the pivot to see which tower is out of alignment or discover a water pressure issue without the right tools.

A simple alert will pinpoint the fault related to alignment, tire inflation*, drive train or water application. Plus, it provides the exact location of the issue on the pivot to eliminate guesswork when troubleshooting.

Maximize Your Uptime

- Know which tower is out of alignment even before arriving at the pivot.

Stay informed about tire pressure status at each tower.* - Monitor individual drive train runtime to keep track of key maintenance intervals at each tower.

- Monitor pivot water pressure at each tower to assure uniform application across the entire field.

*This feature will be available in a future release